Guide to Swagless Fittings

Industrial rope fittings from Electroline offer an efficient and reliable method for terminating wire or synthetic rope in the field. These swageless fittings provide a simple and streamlined alternative to traditional swaged fittings for terminating wire rope. With swaged fittings, a swage press is used to crimp fittings around the end of ropes, exerting tons of pressure to permanently attach the fitting. While swaging creates a strong and durable hold, it is a process that requires specialized equipment.

Swageless wire rope fittings provide all of the strength and reliability of swage fittings without relying on off-site pressing equipment. This allows for flexible on-site installation and even allows for re-termination. When installed properly, swageless fittings can create connections with strength ratings that meet or exceed the breaking strength of most ropes. All of these features make these fittings quick, simple, and strong. The Electroline brand of swageless fittings even has an inspection hole that allows you to know if a fitting is properly assembled.

Electroline specializes in innovative, easy-to-install swageless fittings. These strong and versatile components are available in the following performance materials:

- Self-colored steel

- Zinc-plated steel

- Galvanized steel

- Stainless steel

How do Swageless Fittings Work?

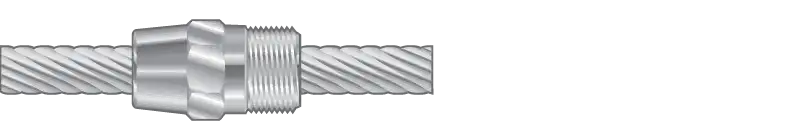

Electroline’s swageless fittings consist of three simple components: a conical plug, a sleeve, and a socket.

These three parts work together to trap the strands of the rope between the body of the fitting and the plug

to create a strong, solid assembly that will meet or exceed the rated breaking strength of most ropes.

How to Install a Swageless Fitting

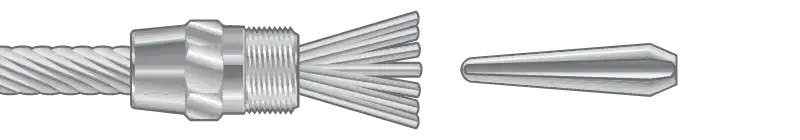

STEP 1

The sleeve is slid over the end of the rope.

STEP 2

The plug is inserted to separate and

hold the rope strands in the sleeve.

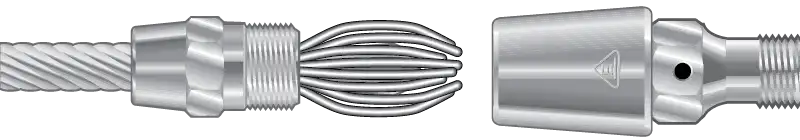

STEP 3

The socket is threaded onto the sleeve

to complete the assembly.

FINAL ASSEMBLY

Twisted strands are visible through the inspection hole

These steps can be performed in the field with no specialized equipment, making swageless fittings far more convenient for many users.

Benefits of Swageless Fittings

The primary advantage of swageless fittings is their quick and easy installation in the field with ordinary hand tools. Many users who need end fittings lack access to expensive swage presses, which makes

swage fittings cost-prohibitive despite their lower unit price. Swageless fittings, on the other hand, can be installed on-site, which can eliminate assemblies that are too long or short while saving time and allowing greater flexibility.

Other benefits of swageless fittings include:

Low-Maintenance

Swageless fittings are built from durable materials that can withstand extreme temperatures and environmental exposures such as precipitation and sea spray. Once installed, they offer lasting performance in even the toughest environments.

Strong

Electroline’s swageless fittings exceed the rated breaking strength of most wire rope or cable. They also feature a unique damping zone to extend the rope’s life.

Versatile

Electroline’s extensive catalog includes a wide range of cast, forged, and machined end fittings with varied designs and finishes. Whatever your industrial rope application, there is a swageless fitting that suits your needs. Additionally, Electroline’s fittings feature reusable components to extend their utility.

Aesthetically Designed

Electroline’s industrial line of fittings can be used instead of rope clamps to create a more attractive termination than rope clamps. Electroline’s architectural line of fittings is ideal for creating smooth, aesthetically appealing connections with no swage marks. Swageless fittings allow designers to achieve open views and modern designs without sacrificing structural stability.

Applications of Swageless Fittings

Swageless fittings have a range of functional and aesthetic applications. They are an ideal choice for cable railings for walkways and bridges, securing backstop netting in baseball stadiums, battleship deck railing, navy ship communication towers, and a broad range of residential, industrial and commercial applications. Their durable construction means they can be used indoors, outdoors, and in extreme environments.

Other common applications of swageless fittings include:

- Recreational and military boat rigging & deck railings

- Lifeline fittings

- Cable railings

- Highway cable barriers

- Zip lines

- Securing sky cams at sporting events

- Amusement park attractions

- Concert rigging

- Airport barriers

- Stadium backstops

- Zoo enclosures

- Military antenna fittings

- Any place where wire or synthetic rope is used

Electroline’s engineering team is also available to work with you on applications that require custom swageless fittings.

Swageless Fittings from Electroline

Electroline has been a leading provider of industrial rope terminations since 1933. Our end fittings are trusted by the U.S. Military and industries such as rigging, utility, architecture, construction, and maritime for their quality and reliable performance.

Electroline’s swageless fittings fall into two main lines: industrial fittings and architectural assemblies.

Industrial Fittings

Our industrial fittings for wire and synthetic rope are used around the world for applications such as highway cable barriers, sports stadiums, sailboats, zoos & and amusement parks, pedestrian walkways, airports, and U.S. military ships.

Available terminations include:

- Clevis/Forked Jaw fittings

- Eye fittings

- Oval Eye fittings

- Studs

- Turnbuckles

- Drum socket fittings

- Hooks

- Swivels

Electroline Swageless Architectural Assemblies

Swageless Architectural Assemblies are designed for indoor and outdoor cable applications. We manufacture these fittings in the U.S. using premium 316 stainless steel for strength and durability. These clean, highly polished, streamlined designs provide more creative options for architectural projects.

This line includes:

- Turnbuckles

- Fixed eye fittings

- Fixed stud fittings

- Accessories and replacement parts

These components make it easier than ever to create secure and attractive terminations in both commercial and residential projects.